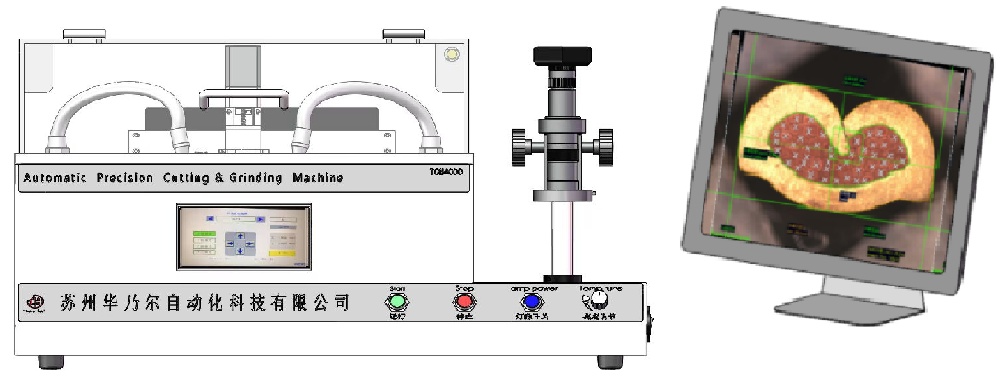

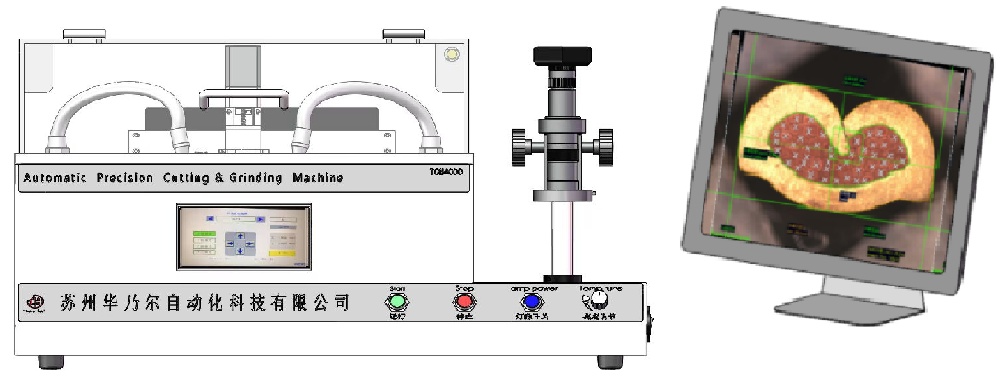

1、 TCM-4000 Usage: This terminal cross-section analyzer is a full body touch screen terminal cutting and grinding instrument, divided into pre cutting treatment, water-cooled precision automatic cutting and automatic grinding. Applicable range of wire diameter AWG6/0-AWG46, 0.008mm ²--- 450mm ²。

This system is suitable for terminal cross-section analysis and testing requirements in fields such as automotive, home appliance, electronics, automation, and new energy.

2、 System Characteristics

1. No resin solidification required

Previously, resin solidification and hardening cutting; Then rough grinding, polishing, time-consuming and laborious, making a sample takes several hours. Now this product does not require resin solidification, making a sample can be completed in about 5 minutes.

2. Fully automatic cutting, grinding and measuring integrated machine

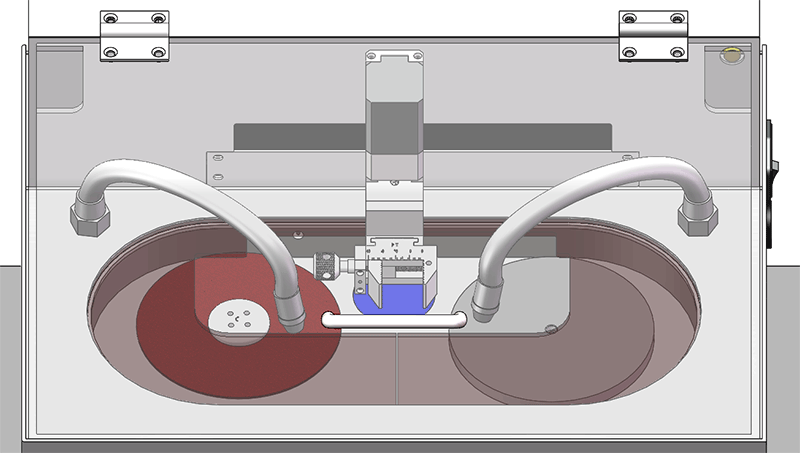

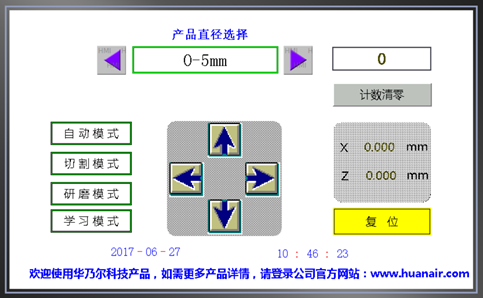

This cutting and grinding all-in-one machine can achieve precision cutting and grinding, with full water cooling. There are four modes, including automatic mode, cutting mode, grinding mode, and "learning mode". This mode can be operated according to pictures (exclusive to the industry); Customers can even customize parameters for personalized cutting and polishing; Visualized cutting position (optional, industry exclusive), with arbitrary setting of cutting position, positioning accuracy within 5um, no damage cutting and polishing.

3. The cutting and grinding machine table has a 7-inch touch screen cross-section in both Chinese and English, with no pressure during operation

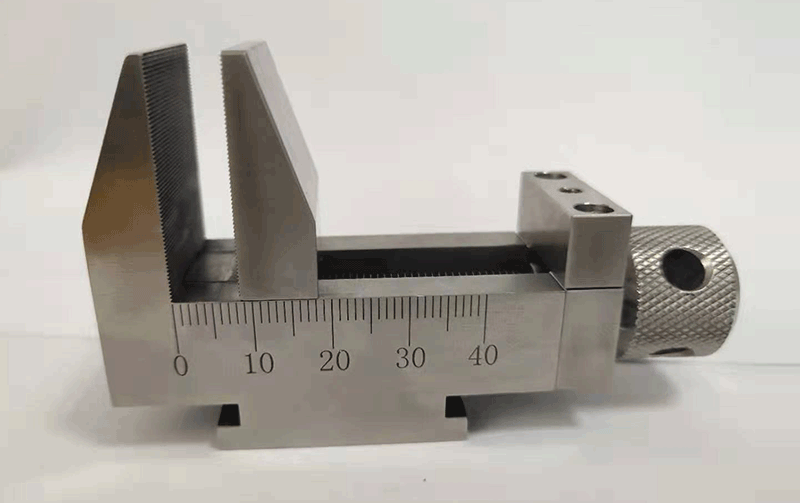

4. Terminal specialized fixtures can correspond to various sizes of terminals

Exquisite stainless steel material fixtures, fine teeth clamping, and excellent assistants for precision cutting to prevent corrosion;

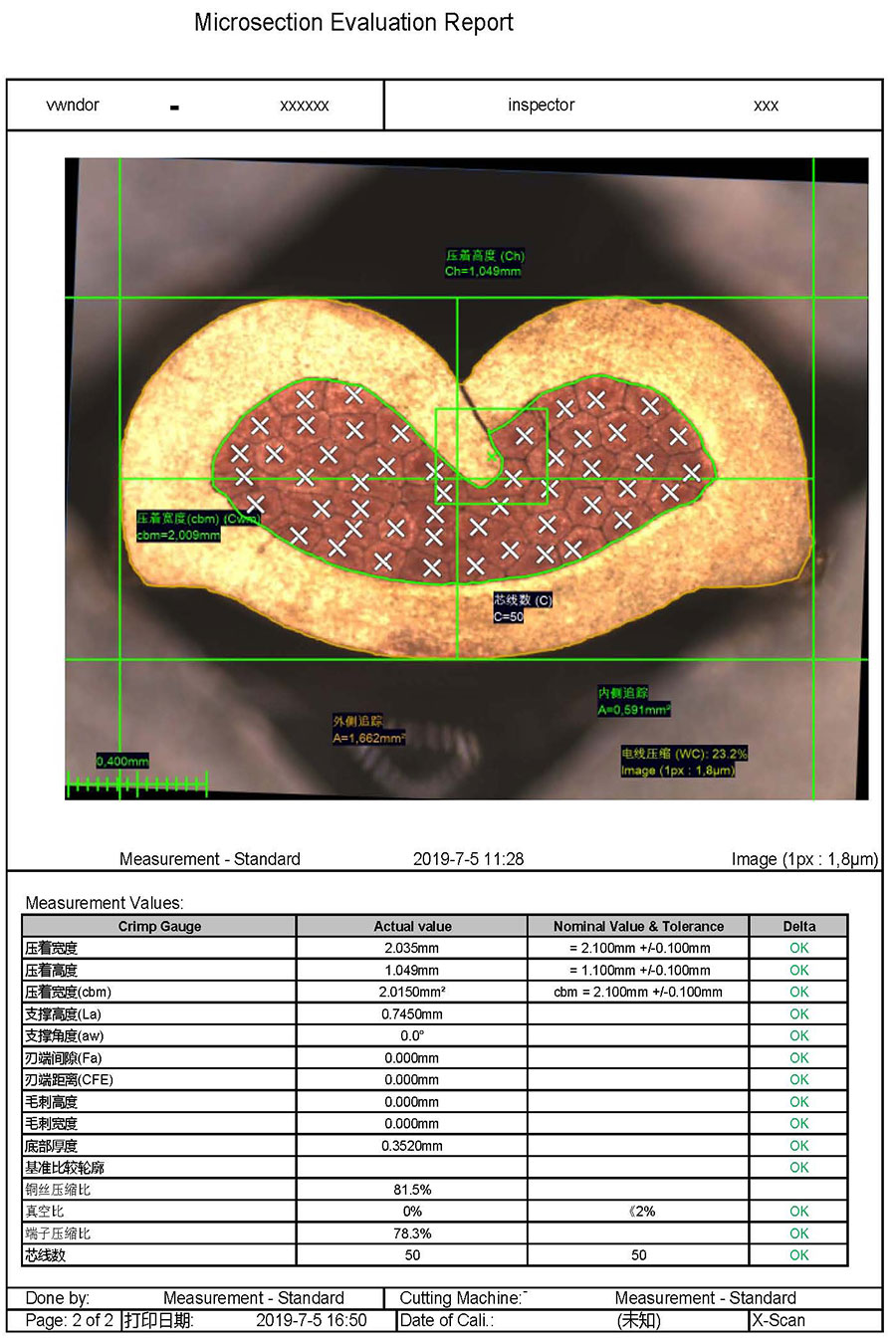

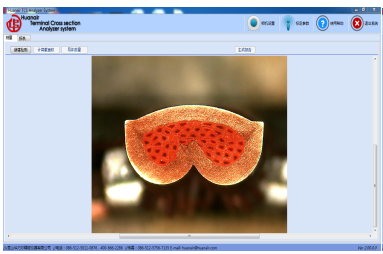

Professional terminal analysis software in both Chinese and English (exported to the Asian and American markets), supporting 32-bit and 64-bit systems for Win XP, Win7, Win8, and Win10; Can analyze over 10 standard test data such as compression ratio C/R, C/H, C/W, and compression ratio.

The software has automatic AI function, and the test product does not need to be placed in the center, as long as it is in the center of the image, it will automatically rotate for testing; Automatic testing, one click export of terminal section test report (Excel format), which can be saved or printed.

3、 System Structure and Configuration

1. German SEW motor high-power precision cutting motor (can achieve power outage stop and continuous cutting functions); Shinano precision grinding and automatic lifting motor from Japan;

2. Color high-definition 7-inch touch screen control

3. Misumi ball screws from Japan and silver slide rails from Taiwan;

4. X-axis Shinano motor;

5. Digital caliper zoom high-definition microscope, high-definition industrial camera: German Basler 1 megapixel CCD camera; 0.2X-1.2X, or choose another 0.7-4.5X lens tube, total video magnification: 18-419X

6. Scope of application: 0.008-450mm2

7. Precision cutting range: 30 * 30mm or diameter ≤ 30mm.

8. Power supply: AC100V~AC240V, overall power: 2500W

9. Imaging system software: Professional terminal image measurement and analysis software (X-Scan), optional with Barcode scanning and MES connection

10. Precision cutting blade: Φ 150X0.5/1.0mm

11. Grinding sandpaper: 150mm/1200#

12. Standard calibration ruler 0.1/10mm

13. Terminal metallographic cleaning solution

14. Lighting source: Integrated pure white LED control light source

15. Integrated computer