This testing machine can independently set control modes such as constant stress, constant strain, and constant displacement, and can smoothly and undisturbed switch between various control modes. It can achieve data processing that meets various standards such as GB, ISO, JIS, ASTM, DIN, etc., with powerful functions and wide applications. It can be used for testing mechanical performance indicators such as tension, compression, bending, shear, peeling, tearing, extraction, and ring stiffness of various metal, non-metallic, and composite materials. It is suitable for testing metal materials such as wire, foil, sheet metal, and bar metal, as well as plastic pipes, plastic profiles, waterproof rolls, geotextiles, wires and cables, textiles, fibers, rubber, ceramics, concrete, adhesives, food and pharmaceutical packaging The mechanical tests of non-metallic materials such as film, wood, and paper can be widely applied in manufacturing enterprises such as mechanical manufacturing, vehicle manufacturing, aerospace, petrochemical, wire and cable, papermaking, textile, construction and building materials, and used for teaching and demonstration in quality supervision and inspection departments, research institutes, and other research departments, as well as universities and vocational colleges.

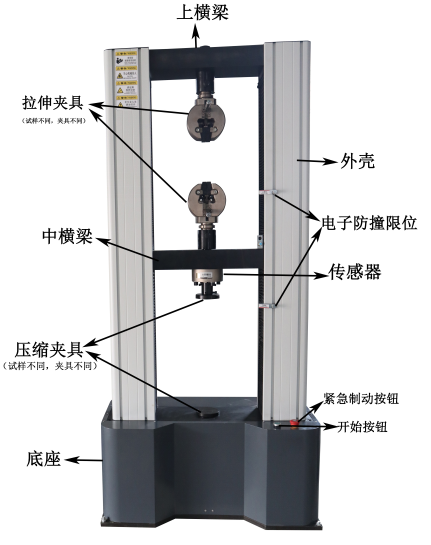

2、 Mechanical structure

Portal structure: This testing machine is equipped with a column and a precision ball screw to fix the upper crossbeam and worktable. It has the characteristics of reasonable structure, high rigidity, stable loading, and good stability.

3、 Technical specifications of testing machine

Main technical indicators:

1. The force measuring sensor is a wheel amplitude tension and compression sensor, with an accuracy of 0.05% FS. The relative accuracy of the system's force measurement is as high as ± 1% within the range of 2% to 100% FS.

2. Electronic extensometer, with an accuracy of Class C, can measure deformation with a relative accuracy of ± 0.5% in the range of 2% -100% FS. (Optional for customers)

3. Main indicators of the measurement and control system:

(1) Three analog input channels are used for force measurement and electronic extensometer measurement, with an AD conversion code of ± 120000 (non segmented measurement achieved with high-resolution AD converter is better than 4-stage amplification).

(2) A digital output channel with a 1:100 speed ratio, used to control the servo system for stepless speed regulation within the range of 2-200mm/min.

(3) Three optoelectronic coding input channels are used for measuring large deformation and displacement measurement, using quadrupling technology to improve measurement resolution.

(4) A manual operation box that can quickly adjust the test space, shorten the test duration, and complete the test relatively quickly.

4、 Various technical parameters

(1) Host parameters:

1. Maximum stretching space (mm): 600;

2. Maximum stroke of moving crossbeam (mm): 1000;

3. Test width (mm): 400;

4. Maximum speed for beam adjustment (mm/min): 500;

(2) Measurement parameters:

1. Maximum test force (kN): 50; (100N-50KN force value optional)

2. Testing machine level: 0.5 level;

3. Test force measurement range: 1% to 100% F S (maximum load);

4. Test force measurement accuracy: better than ± 0.5% of the indicated value;

5. Test resolution: 1/300000 of the full scale (with only one resolution in the full range and no grading);

6. Displacement measurement accuracy: ± 1%;

(3) Control parameters:

1. Stress control rate range: 0.05-5% FS/s;

Stress control rate accuracy: within ± 2% of the set value when the rate is less than 0.05% FS/s, and within ± 0.5% of the set value when the rate is ≥ 0.05% FS/s;

3. Strain control rate range: 0.05-5% FS/s;

Strain control rate accuracy: within ± 2% of the set value when the rate is less than 0.05% FS/s, and within ± 0.5% of the set value when the rate is ≥ 0.05% FS/s;

4. Displacement control rate range: 0.05~500mm/min;

Displacement control rate accuracy: When the rate is less than 0.5mm/min, it is within ± 1% of the set value, and when the rate is ≥ 0.5mm/min, it is within ± 2% of the set value;

(4) Machine parameters:

1. Host size (mm): approximately 815 × three hundred and sixty × 1650mm;

2. Host weight (kg): approximately 250;

3. Power (kW): 0.75;

4. Power supply: single-phase, 220V;

5. Usage environment: No vibration or dust; room temperature