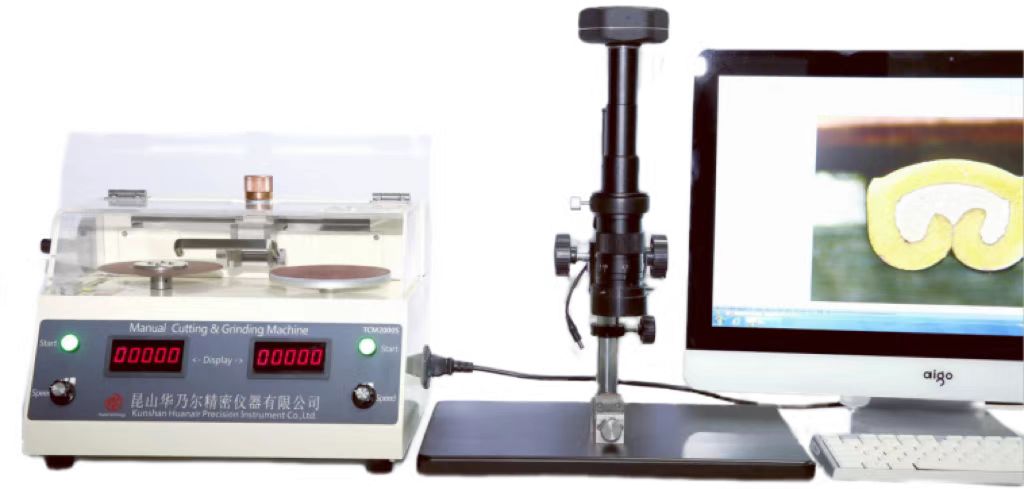

简单介绍(Briefly Introduction)

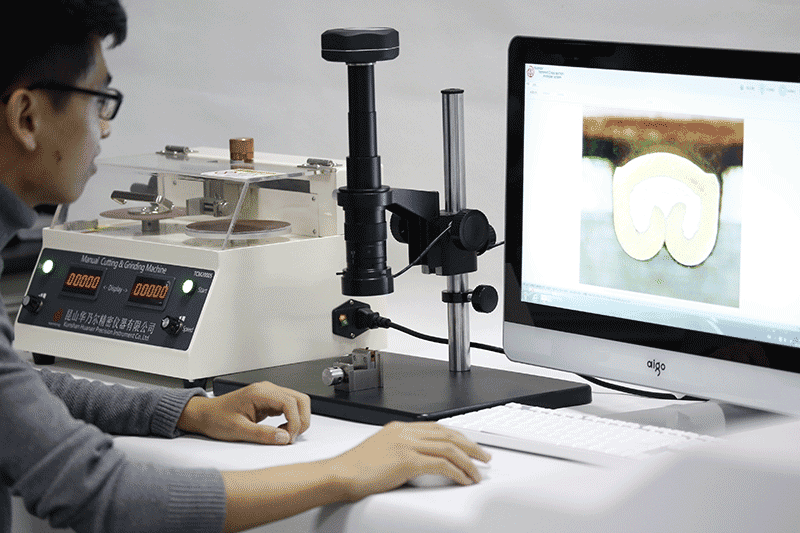

This terminal section analyzer is the first special instrument for testing terminal section developed by Huanell Technology in Chinese Mainland in 2006, and also the first test instrument developed in China. After more than 10 years of continuous optimization, it meets the customer's personalized needs from hardware to software, not just a set of standards for a brand of automotive wiring harness industry, but can completely customize product standards and make judgments according to the internal needs of enterprises. At present, there are over a hundred users involved in various fields such as automobiles, home appliances, electronics, electrical appliances, new energy, aerospace, high-speed rail, etc.

Main features:

1. Four fold cutting safety protection to ensure personnel safety during cutting;

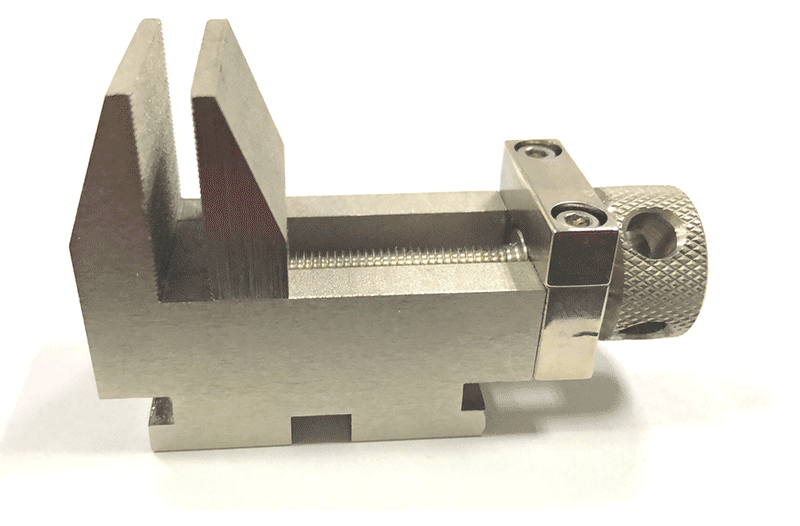

2. The fixture is made of 45 # bearing steel that has undergone high-temperature hardening treatment (non aluminum) to prevent clamping wear and tooth end loosening.

3. After the grinding disc is installed on the machine, CNC precision milling is used to ensure full flatness and smoothness

4. The cutting disc is adjusted in three directions using XYZ, and the perpendicularity is calibrated with a dial gauge

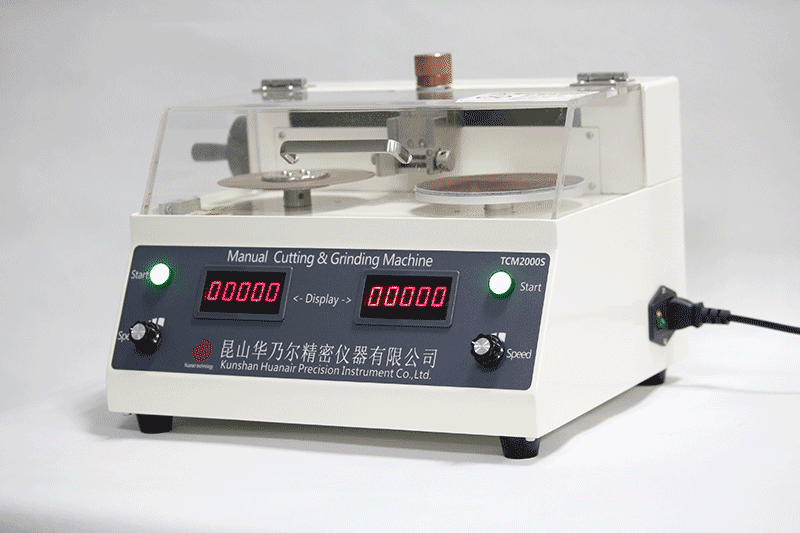

1、 TCM 2000S Usage: This terminal cross-section analyzer is a one piece terminal cutting and grinding instrument, including cutting and grinding. Making a sample can be completed in about 5 minutes, with a wire diameter range of AWG00-AWG46 and a maximum clamping diameter of 10mm. This system is suitable for terminal cross-section analysis and testing requirements in industries such as automotive, home appliances, and electronics.

二、TCM 2000S系统特点(Characteristic)

2.1无需树脂凝固(Without resin solidification);

2.2端子专用夹具,适用于不同规格的端子(special Terminal fixture, suitable for different kinds of terminal blocks);

标准夹具适用于AWG00~AWG46线(suit for AWG00~AWG46);

2.3本设备可对切割时可进行端子上下切割位置调整(The device can be carried out while cutting the vertical cutting position adjustment terminal);

2.4方便测量端子压接高度、宽度毛刺尺寸、壁厚、铜丝数量、压缩比、压接面积等计算(Easy to measure terminal crimp height, width burr size, wall thickness, the number of copper wire, the compression ratio , crimping and area calculation);

2.5一键式导出报告(One-click Export excel Report);

Exquisite stainless steel material fixture, fine tooth clamping, a good assistant for precision cutting, corrosion-resistant;

2.7.Professional terminal analysis software in both Chinese and English (exported to the Asian and European markets), supporting the Windows operating system; Can analyze over 10 standard test data such as compression ratio C/R, C/H, C/W, porosity, etc., fully meeting standards such as VW60330, Renault 36-05-019/- G, PSA 9634115099, QC T 417.1-2001, etc; You can also customize testing standards without worrying about them; Accurately locate the testing location, provide a concise screen, and export the terminal section testing report (Excel format) with one click, which can be saved or printed.

三、系统结构(System Structure)

1. 端子截面分析(Terminal Analyze):进口连续变倍光学系统(Imported continuous variable power optical system);物镜倍率0.7—4.5X

2. 视频总倍率(Video total magnification):65~419X

3. 适用线径范围:AWG00-AWG46,0mm2---50mm2,

4. 电源(Power supply):AC100V~AC240V 功率(P)350W

5. 成像系统(Imaging Systems): 德国Balser 500万高清彩色数字CCD摄像头(German Balser 5 million high-definition color digital CCD camera)

6. 切割片规格:Φ100X0.5mm

7. 研磨砂纸(Polishing sandpaper):125mm/ 1500#,

8. 华乃尔精密一体式切割研磨设备(Model),TCM2000S;

9. 专业端子截面分析软件(Professional terminal section analysis software ),

10. 高精度基准尺(Standard optical device):0.1/10mm

11. 端子金相配件(Cleaning liquid)

12. 照明光源(Lighting):可调白光照明装置

13. 22 inch computer integrated

| XX汽车部件有限公司 | |||||||||||

| 端子截面分析报告 | |||||||||||

| Terminial Cross Section Analyzer Report | |||||||||||

| 制造商 | 苏州XXX汽车部件有限公司 | 送检日期 | 2013-7-20 | ||||||||

| 联系人 | 赵XX | 上下模规格 | 机台号 | M13# | |||||||

| 端子/线型 | T3231/AWG18 | 线型 | AWG 18 | ||||||||

| 测量设备 | TCM2000S | ||||||||||

| |||||||||||

| 测试结果 | 名称 | 数值 | 标准 | 结果 | |||||||

| Name | Value | Standard | Result | ||||||||

| 端子压接高度 | 2.250mm | '+/-0.05mm | √ | ||||||||

| C/H:Crimp Height | |||||||||||

| 端子压接宽度 | 3.884mm | '+/-0.05mm | √ | ||||||||

| C/W:Crimp Width | |||||||||||

| 高度/宽度比率 | 57.9% | % | √ | ||||||||

| (C/H)/(C/W) | |||||||||||

| 初始电线面积 | 3.000 | As requirement | √ | ||||||||

| Initial area | |||||||||||

| 原端子厚度 | 0.400 | As requirement | √ | ||||||||

| Original thickness | |||||||||||

| 端子压接面积 | 2.570mm2 | / | √ | ||||||||

| Terminal crimping area | |||||||||||

| 截面缩小比 | 14.3% | 5%--35% | √ | ||||||||

| Narrow cross-section than | |||||||||||

| 压缩比率 | 85.7% | 65%--95% | √ | ||||||||

| C/R:Compression Ratio | |||||||||||

| 压接线数 | 37 | As requirement | √ | ||||||||

| Cross count | |||||||||||

| 支撑角度 | 3.892 | 0≤α≤30度 | √ | ||||||||

| Bending angle | |||||||||||

| 毛刺高度 | 0.049mm | ≤1X底厚 | √ | ||||||||

| B/H:Burr Height Gh | |||||||||||

| 毛刺宽度 | 0.266mm | ≤0.5X底厚 | √ | ||||||||

| B/H:Burr Width Gb | |||||||||||

| 支撑高度 | 0.461mm | ≥1X底厚 | √ | ||||||||

| La Supporting height | |||||||||||

| 底部厚度 | 0.388mm | ≥0.75X底厚 | √ | ||||||||

| B/T:Base Tickness | |||||||||||

| 羽翼末端间距 | 0.021mm | ≤0.5X底厚 | √ | ||||||||

| CFE:Crimp Face Ends | |||||||||||

| 压接翼与底部高度差 | 0.383mm | ≥0.5X底厚 | √ | ||||||||

| F/C:Face End Clearance | |||||||||||

| 间隙率 | 14.3% | 5%--35% | √ | ||||||||

| Air inclusions | |||||||||||

| EDGE(毛刺)宽率 | 18.3% | % | |||||||||

| Burr Width Ratio | |||||||||||

| 壁厚变化率 | % | ||||||||||

| Base Thickness Ratio | |||||||||||

| 端子拉力测试 | % | ||||||||||

| Pull Strength | |||||||||||

| 外观判定 | |||||||||||

| 1.线芯未呈蜂窝形或有间隙 | √ | 2.羽翼至端子壁距离过近 | √ | ||||||||

| 3.羽翼至端子底距离过近 | √ | 4.毛刺高度大于材料厚度 | √ | ||||||||

| 5.毛刺宽度大于材料宽度的1/2 | √ | 6.压接部位与端子体之间扭曲 | √ | ||||||||

| 7.羽翼尖高度差超出材料厚 | √ | 8.压接裂纹 | √ | ||||||||

| 9.羽翼未封闭或弹起 | √ | 10.芯线漏出或夹在羽翼中间 | √ | ||||||||

| 合格/**切片照片若有1-10项中任何一不合格项(被选中),此压接即为不合格 | OK | ||||||||||

| 备注 | |||||||||||

| 检测人 | 周小姐 | 检测日期 | 2013-7-20 | ||||||||