Brief Introduction

This metallographic cutting and grinding machine is the first special instrument for testing terminal profile developed by Huanell Technology in Chinese Mainland in 2006, and also the first test instrument developed in China. After more than 10 years of continuous optimization, it meets the customer's personalized needs from hardware to software, not just a set of standards for a brand of automotive wiring harness industry, and can completely customize product standards and make judgments according to the internal needs of enterprises. At present, there are over a hundred users involved in various fields such as automobiles, home appliances, electronics, electrical appliances, new energy, aerospace, high-speed rail, etc.

Main features:

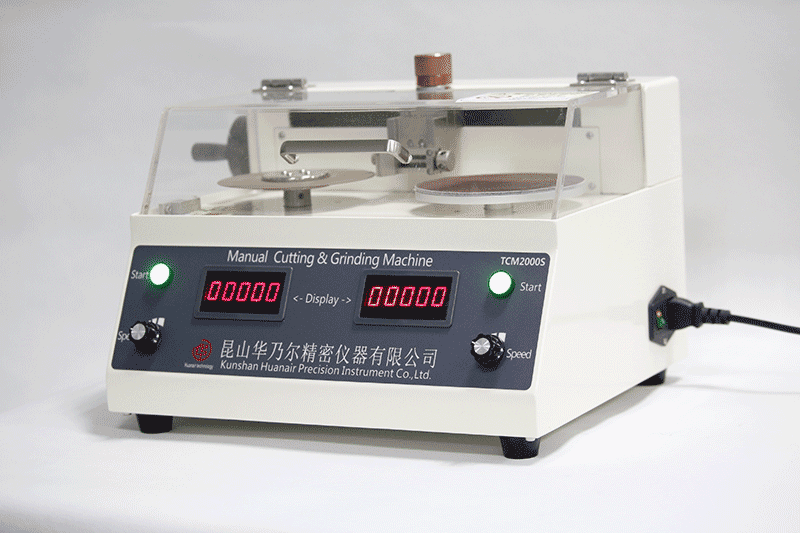

1. Four fold cutting safety protection to ensure personnel safety during cutting;

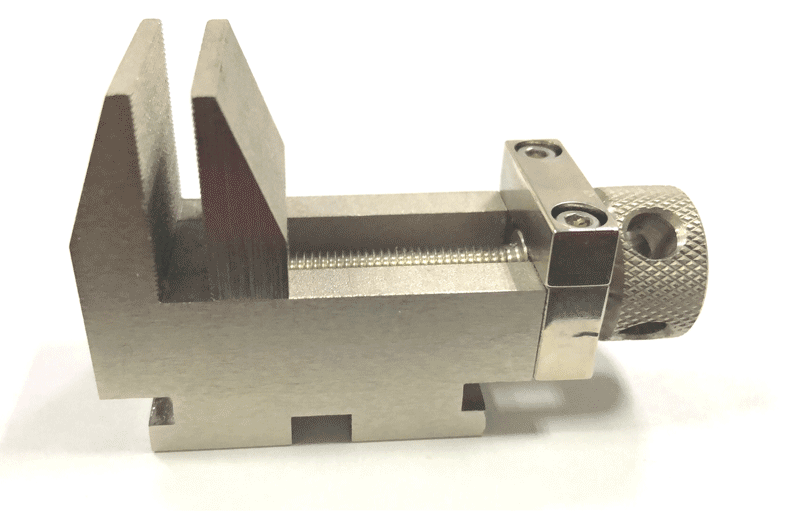

2. The fixture is made of 45 # bearing steel that has undergone high-temperature hardening treatment (non aluminum) to prevent clamping wear and tooth end loosening.

3. After the grinding disc is installed on the machine, CNC precision milling is used to ensure full flatness and smoothness

4. The cutting disc is adjusted in three directions using XYZ, and the perpendicularity is calibrated with a dial gauge

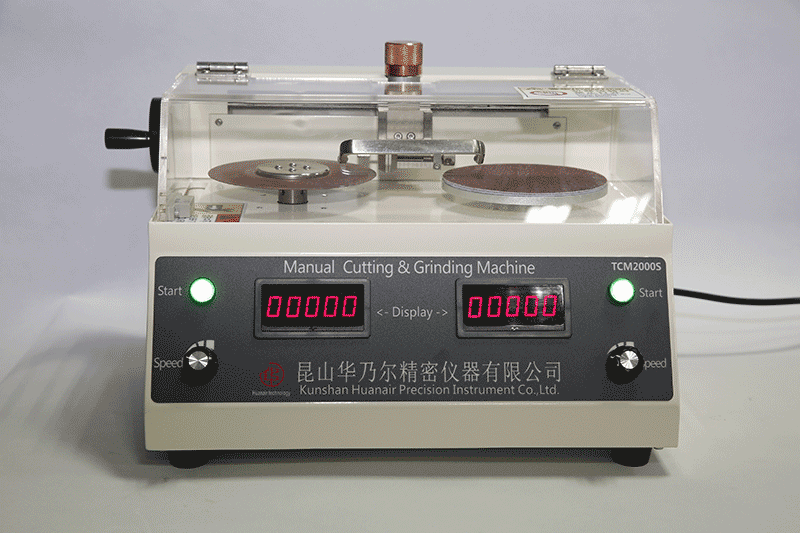

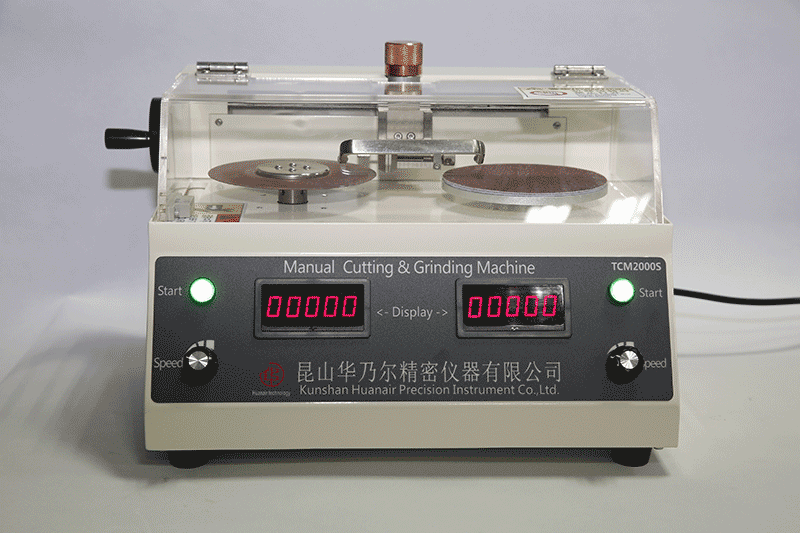

1、 TCM-2000S Usage: This metallographic cutting and grinding machine is a one piece metallographic cutting and grinding instrument that automatically cuts and grinds, with a maximum clamping diameter of 10mm.

2.1无需树脂凝固(Withoutresinsolidification);

2.2本设备可对切割时可进行端子上下切割位置调整(Thedevicecanbecarried outwhile cuttingthe verticalcutting positionadjustmentterminal);

2.3样品装夹方便,切割及研磨只需装夹一次,且在同一平面,取下样品时连同夹具一起,放在显微镜下观察,确保观察面的平面度(Sample clamping is convenient, cutting and grinding only need to be clamped once, and in the same plane, when taking down the sample, together with the clamp, placed under the microscope to observe, to ensure the flatness of the observation surface)

2.4切割非常平整,研磨后基本接近2000号水磨样品的水平(The cutting is very smooth and the grinding is almost close to the level of2000 water-milling sample)。

2.5端子专用夹具可对应各种尺寸的端子Special fixtures can correspond to samples of various sizes

精美的不锈钢材料夹具(别家为铝材,易磨损),细牙夹持,精密切割的好助手,耐腐蚀

Exquisite stainless steel material fixture, fine tooth clamping, a good assistant for precision cutting, corrosion-resistant;

三、系统结构(System Structure)

1..华乃尔精密一体式自动切割研磨设备(Model),TCM-2000S;

2.适用切割范围:直径20mm以内

3.最大夹持直径20mm,精度:2µm

4.电源(Power supply):AC100V~AC240V功率(P)350W

5.切割片规格:Φ125X0.5mm

6.研磨砂纸(Polishing sandpaper):125*1200#