A brief introduction

The hardness tester software utilizes the analysis results provided by the software to provide more scientific basis for enterprise quality control, improve enterprise management level and external image, and is an effective tool for enterprises to engage in the development of new technological products and product quality monitoring. This software can also serve as an effective tool for theoretical teaching, experimental analysis, and basic scientific research in research institutions, manufacturing factories, colleges, and other departments related to metal materials

Detailed introduction of hardness tester software

Micro hardness tester software - hardness tester automatic measurement software YI

1、 Purpose

Suitable for various production enterprises related to metal material products, such as steel production, shipbuilding, automobile manufacturing, aircraft manufacturing, high-pressure vessels, electrical components, bearings, standard parts, hardware and textile accessories, and instrument and meter accessories. The analysis results provided by this software can provide more scientific basis for enterprise quality control, improve enterprise management level and external image, and is an effective tool for enterprises to engage in the development of new technological products and product quality monitoring. This software can also serve as an effective tool for theoretical teaching, experimental analysis, and basic scientific research in research institutions, manufacturing factories, colleges, and other departments related to metal materials

2、 Function:

Computer measurement image analysis, precise correction of hardness software, and gradient visualization. It can also be measured with an eyepiece. Output measurement data, images, metallographic images, and hardness gradient maps, which can be printed or saved

Introduction: This machine is a hardness tester that combines a computer microcomputer measurement system with a hardness tester. This computer microcomputer measurement system can be equipped with various types of hardness testers.

Technical performance:

*Use a high-resolution image acquisition device to clearly display the indentation on the computer screen.

*Image clarity:>480 lines.

*Supports PAL cable NTSC color/black and white video inputs.

*Measure the hardness value of the test indentation by converting the signal through software.

*Experiments can be conducted on micro Vickers, Knudp, carburized layer, nitrided layer, etc.

*The hardness value can be automatically converted in various forms.

*The contrast and brightness of the indentation image can be adjusted.

*Perform automatic framing measurement on the indentation and display depth intensity.

*Edge detection can be performed on the indentations obtained from samples with poor smoothness.

*Indentation can be 2 ×、 Zoom in to better measure the experimental values.

*Image files and data files can be opened, stored, and printed separately.

*You can view data files and image files at any time, and the data files are printed in the form of tables and curves.

*You can choose a high-power or low-power objective as needed.

*Supports operating systems such as WIN9X, WIN2000, and WINXP.

Can be configured on various Vickers/Knoop hardness testers such as 401MVA, 402MVA, HX-1000, HV-1000, HXS-1000, etc

3、 Operating instructions:

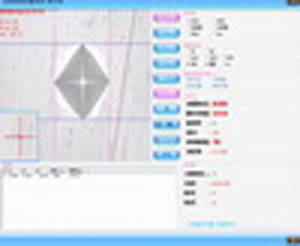

This interface mainly consists of two parts, the left part is the graphic display area and the manual selection workspace. This section displays the indentation taken and the point used for manual collection. The right part is the operation buttons, which from top to bottom are: image analysis, new sampling, continue sampling, stop, data display, read graphics, save graphics, print images, system settings, zoom in, help, change HK pressure head, change HV pressure head, HB pressure head, change angle measurement, and change length measurement.

1. Image analysis, new sampling: This button is used to switch between sampling and analysis.

2. Continue sampling, stop: Similar to the same button. This button is also used to switch between image acquisition and analysis. The difference is that the data analyzed by this button automatically becomes a series of data sets, which can be used for analysis work entering the carburized and nitrided layers.

3. Data display: Used to display the collected and processed data, as well as further analyze the carburized and nitrided layers.

4. Reading graphics: The previously saved graphics can be read out for viewing or reanalysis.

5. Save graphics: The graphics currently displayed in the display area can be saved for future viewing and analysis.

6. Print graphics: Send the graphics currently displayed in the display area to the printer for printing.

7. Change HK/HV indenter/HB indenter/angle measurement/length measurement: Replace with four different attack energies.

8. System settings: Various parameters during the experiment can be modified, such as head pressure and other parameters. The various parameters of the sample can be modified and adjusted. The adjustment of these parameters will affect the accuracy of the entire system. Generally, it is not advisable to change them easily. Graphic adjustment: can adjust the contrast, brightness, and other data of the displayed graphics in the display area.

9. Enlarge: The display area of the graph can be enlarged several times to facilitate viewing of details related to the image.

10. Help: When you need to understand the operation of this system; And consult commonly used heat treatment processes and hardness change tables